Features

- 1. Glass strength is equivalent to float glass.

- 2. FireLite can be cut with a standard glass-cutter.

- 3. When broken, it will crack radially like float glass.

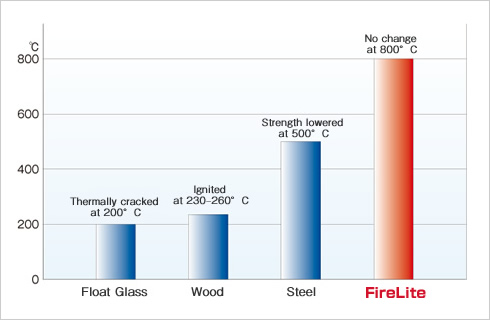

Heat-resistance of Comparing

FireLite heated to 800℃ does not crack even if sprayed with cold water.

FireLite is also resistant to repeated heating processes.

Pattern

Neo- Clear and High transparency

Mist- Hazy pattern controls light

Size

| Size(㎜) \ Pattern | FireLite Neo | FireLite Mist |

|---|---|---|

| 914×2,438×5t | ● | ● |

| 1,219×2,438×5t | ● | ● |

*Please contact us about 914×2,438×8t and 1,219×2,438×8t sizes and FireLite Plus sizes.

Property

| Properties | FireLitet | Float Glass | ||

|---|---|---|---|---|

| Flat Panel | Visible Ray Transmittance | t=5㎜, %) | 87 | 89 |

| Refractive Index | (nD) | 1.54 | 1.52 | |

| Curved Panel | Thermal Expansion Coefficient | 30~750℃, ×10-6/℃) | -0.3 | 8.5 |

| Specific Heat |

(25℃, J/g・K) | 0.71 | 0.76 | |

| Thermal Conductivity | (25℃, W/m・K) | 1.51 | 0.76 | |

Precautions for Design and Installation

- 1. The glass strength of FireLite is equivalent to that of float glass of the same thickness.

- 2. FireLite can be easily cut with a glass cutter, like float glass.

- 3. When broken, FireLite cracks radially like float glass.

- 4. FireLite cannot be bent.

Surface quality of FireLite

FireLite is manufactured through a crystallization process. For this reason, distortions in reflected images on FireLite are larger than those on float glass.

Due to the manufacturing method, fine bubbles may be generated on the surface, but they do not affect the product performance.

Warning

FireLite is not a tempered glass; its strength is almost the same as that of float glass. When people or objects come into contact with FireLite, the glass may be broken and cause serious injury.

・To minimize the risk of accidents attributed to broken glass, please review the wind pressure resistance strength and select an appropriate size and thickness of FireLite for such applications as windows and exterior doors.

・When using FireLite for entrances, atriums, zones around escalators, and other locations where people or objects are likely to come into contact with the glass, please apply films to prevent glass splash.

※NEG conducted specified fire protection equipment performance validation tests on FireLite on which glass splash prevention films were applied, and confirmed that the FireLite performance was not affected. (Films used to conduct performance validation tests: SCLARL400 manufactured by Sumitomo 3M Limited)